What is a bioplastic?

Most of the plastics we currently use come from fossil sources. In other words, the carbon they contain comes from petroleum-derived products. As a result, their degradation releases into the environment carbon previously trapped underground. The steady increase in carbon dioxide concentration in the atmosphere since the Industrial Revolution is an undeniable fact. Its potentially serious effects on the climate have prompted the search for ways to reduce the carbon footprint of our industrial activities, and one of these is the replacement of conventional plastics with renewable alternatives.

The industry has developed for this purpose a range of materials collectively known as bioplastics. The idea is that using raw materials from plant sources, the balance would be neutral, as the emitted carbon would have been previously captured (and recently, not over geological timescales) by plants. It’s important to highlight that the carbon footprint of a product is not solely that of its raw material, but also includes processing, storage, and transportation phases that might not be decarbonized: the calculation method is defined by the ISO 14067 standard (Carbon footprint of products – Requirements and guidelines for quantification).

However, when seeking a concrete definition of bioplastics, things become complicated. According to European Bioplastics, a European association of bioplastics manufacturers that brings together many leading companies in the sector, bioplastics are a family of materials that includes products that are bio-based, biodegradable, or both. In fact, bioplastics can be produced from renewable sources like cellulose, they can be synthesized from monomers produced through biotechnological processes, or they can be biodegradable plastics derived from fossil sources. In other words, bioplastics are loosely defined materials, and under this heading, a wide variety of typologies can be found. Let’s explore the issue more in detail.

First, a material is considered biobased when it is produced from biomass, meaning it is obtained from plants, algae, microorganisms, or any other biological source. The criterion is reasonably clear, although most definitions like the one provided by the cited European Commission or the United States Environmental Protection Agency include partially biobased materials in the bio-based category.

As for biodegradability, there are standardized norms for quantifying it in different environments, such as ISO 19679 related to the interface between marine water and sediments, or ISO 14851 which determines the aerobic biodegradability of plastic materials in aqueous environments. However, biodegradability is not an on-off concept. All organic materials are potentially biodegradable, although in some cases, the process might take a long time. A key issue is that a biodegradable product is not designed to be discarded into the environment, as highlighted a few years ago in a famous article by Richard Thompson (the same person who coined the term 'microplastic'), which demonstrated how a biodegradable bag was capable of surviving in the sea for years.

That’s why instead of biodegradability, it’s preferable to use the term compostability, which refers to biodegradability under industrial composting conditions and is quantified as indicated in the standard ISO 14855-1 (determination of the ultimate aerobic biodegradability of plastic materials under controlled composting conditions). Achieving proper composting is not a straightforward task, and degrading bioplastics might require a significant amount of time even in well-designed composting facilities.

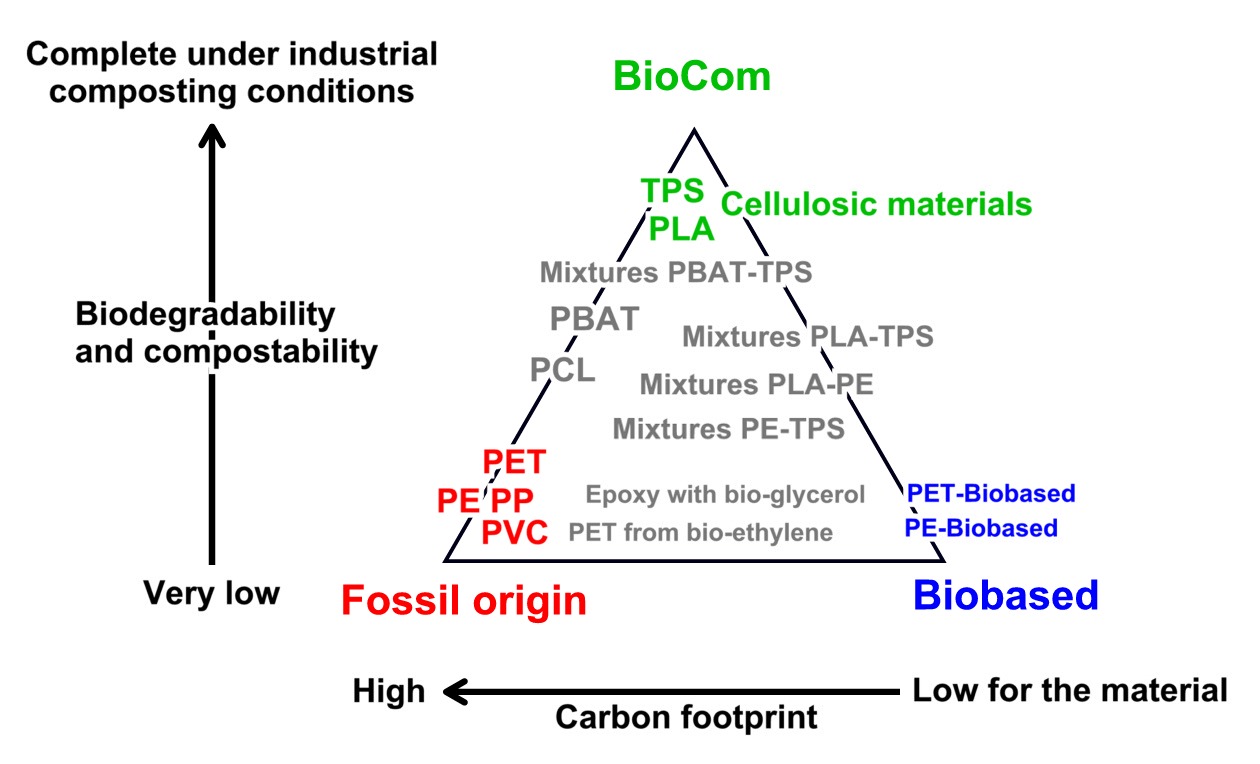

All plastics, not only bioplastics, can be classified based on their compostability (compostable/non-compostable) or their material carbon footprint (fossil-based/bio-based), as shown in the Figure. It’s important to emphasize that this classification refers to the polymer that forms the plastic, not to the additives the plastic may incorporate (sometimes in proportions as high as 40% by weight). Materials that are both compostable and bio-based are referred to as BioCom, which some authors consider to be the true bioplastics.

The figure includes some compostable (biodegradable) plastics of fossil origin, as it is possible to synthesize compostable materials from petroleum. This is the case for poly(butylene adipate-co-terephthalate) (PBAT) or polycaprolactone (PCL). It is also possible to synthesize non-biodegradable or traditional polymers like polyethylene (PE) from renewable sources, using conventional petrochemical synthesis routes.

.It’s important not to confuse biodegradable plastics with oxo-degradable or oxo-plastics, which are conventional plastics that included additives to accelerate their fragmentation through heat or exposure to sunlight. These materials were true sources of microplastics and were banned in Europe under Directive (EU) 2019/904 on reducing the impact of certain plastic products on the environment.

However, it’s important to take into account that:

1. Plastics consist not only of the polymer, as it also contains additives; besides, its carbon footprint can also stem from manufacturing and distribution processes.

2. The management of bioplastics at the end of their life isn’t always clear, as they might be recyclable (sharing bin with packaging), compostable (biowaste bin), or both. (Furthermore, distinguishing a bioplastic from a conventional plastic isn’t always easy.)

3. Producing plastic from plant sources can divert arable land from food production.

4. Biodegradable plastics are also less stable than conventional ones, which can result in toxicity due to faster release of additives or the emission of nanoplastics.