How biodegradable are biodegradable plastics?

In a previous post, the different types of bioplastics were introduced. It was shown that bioplastics constitute a family of materials that includes bio-based and biodegradable materials. When both characteristics occur simultaneously, the bioplastic, being both bio-based and compostable at the same time, is referred to as BioCom. It is important to emphasize the distinction between ‘biodegradable’ and ‘compostable’. A biodegradable material is one that can break down through the action of biological agents such as bacteria or fungi over a certain period of time and under unspecified or natural conditions. A compostable material is necessarily biodegradable, but additionally, it must degrade under precisely specified conditions, resulting in a material similar to humus that can serve as fertilizer or organic soil amendment.

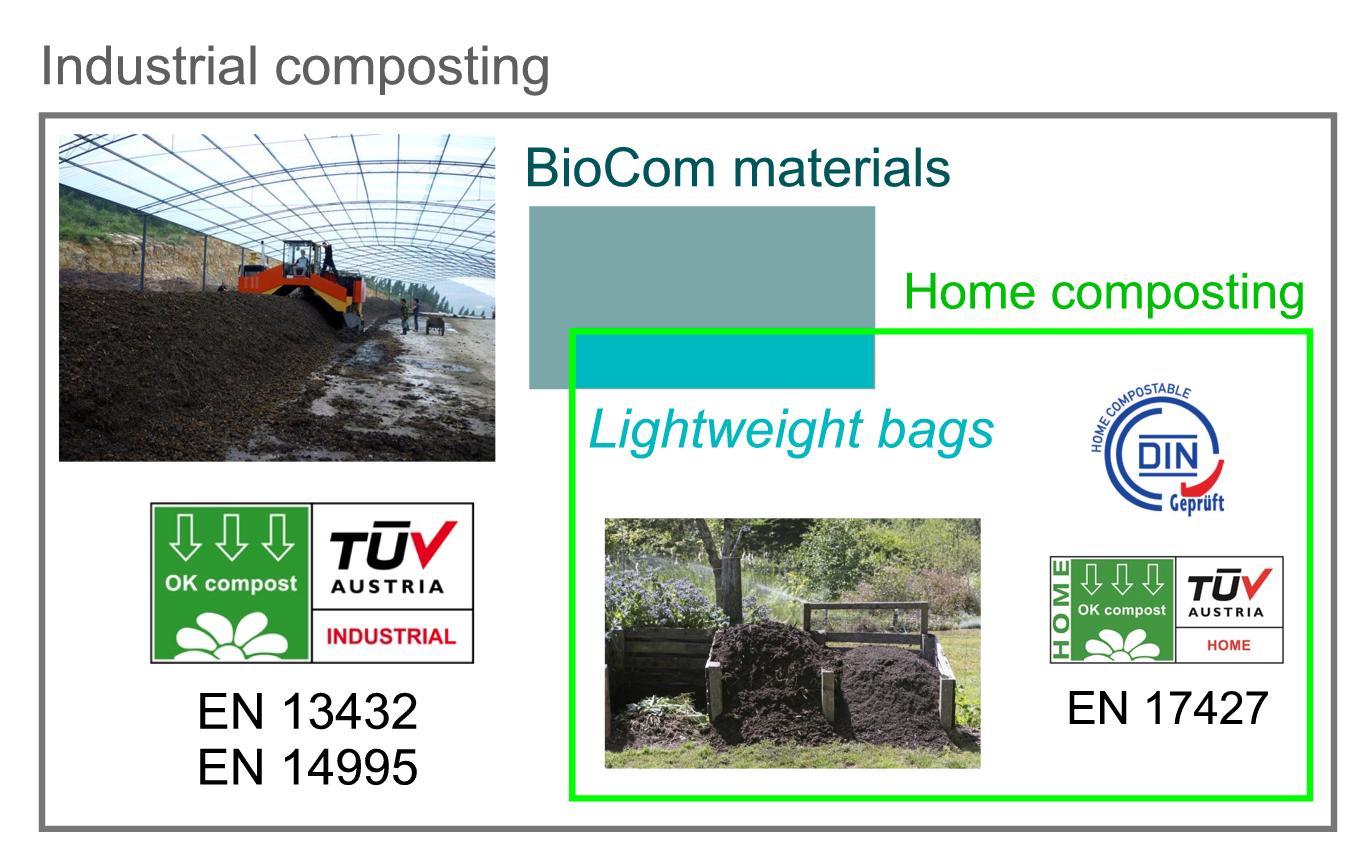

Composting is an aerobic process (although it can be applied to the residue of anaerobic digestions aimed at producing methane) carried out in both industrial and household settings. In some countries, household composting is very popular. However, it is important to note that home composting is not simply a scaled-down version of the industrial process; they are two different methods. Household composting promotes personal responsibility in waste management and streamlines the treatment of portions that otherwise would reach centralized management facilities. Nevertheless, the conditions for the process, such as temperature, humidity, and aeration, are challenging to control in home devices and differ substantially from those maintained in industrial facilities. In the latter, compost piles are consistently aerated, humidity is controlled, and temperatures of up to 65 °C are reached. Such conditions support the growth of thermophilic microorganisms and maintain a high biological diversity. As a result, decomposition times are significantly reduced in comparison to home composting.

Bioplastics are not generally suitable for home composting. Industrial compostability is regulated by standards such as EN 13432 (packaging) and EN 14995 (general). Various entities like DIN Certco or TÜV-Austria certify the compostability of materials, and there is even a recent European standard (July, 2023) certification materials for home composting systems (EN 17427: Packaging – Requirements and test scheme for carrier bags suitable for treatment in well-managed home composting installations.). The most significant difference is that while home composting systems operate at room temperature (typically 25 °C), the industrial ones are certified at 58 °C. This is why specific certifications like TÜV OK Compost Home exist.

Domestic composting works reasonably well with lightweight bags. These are films made from thermoplastic starch and bioplastics such as poly(lactic acid), which degrade in industrial composters over a period ranging from a few weeks to several months, depending on the conditions and technology used (compliance with the EN 13432 standard requires at least 90% degradation within 6 months). In household piles, the process is much slower and can take a year or more, which might lead to suspicions of fraudulent certification, though this is not necessarily the case. Recent research in this regard can be found in the original publication, and its media coverage is documented in the review published in The Age of Extinction section of The Guardian newspaper.

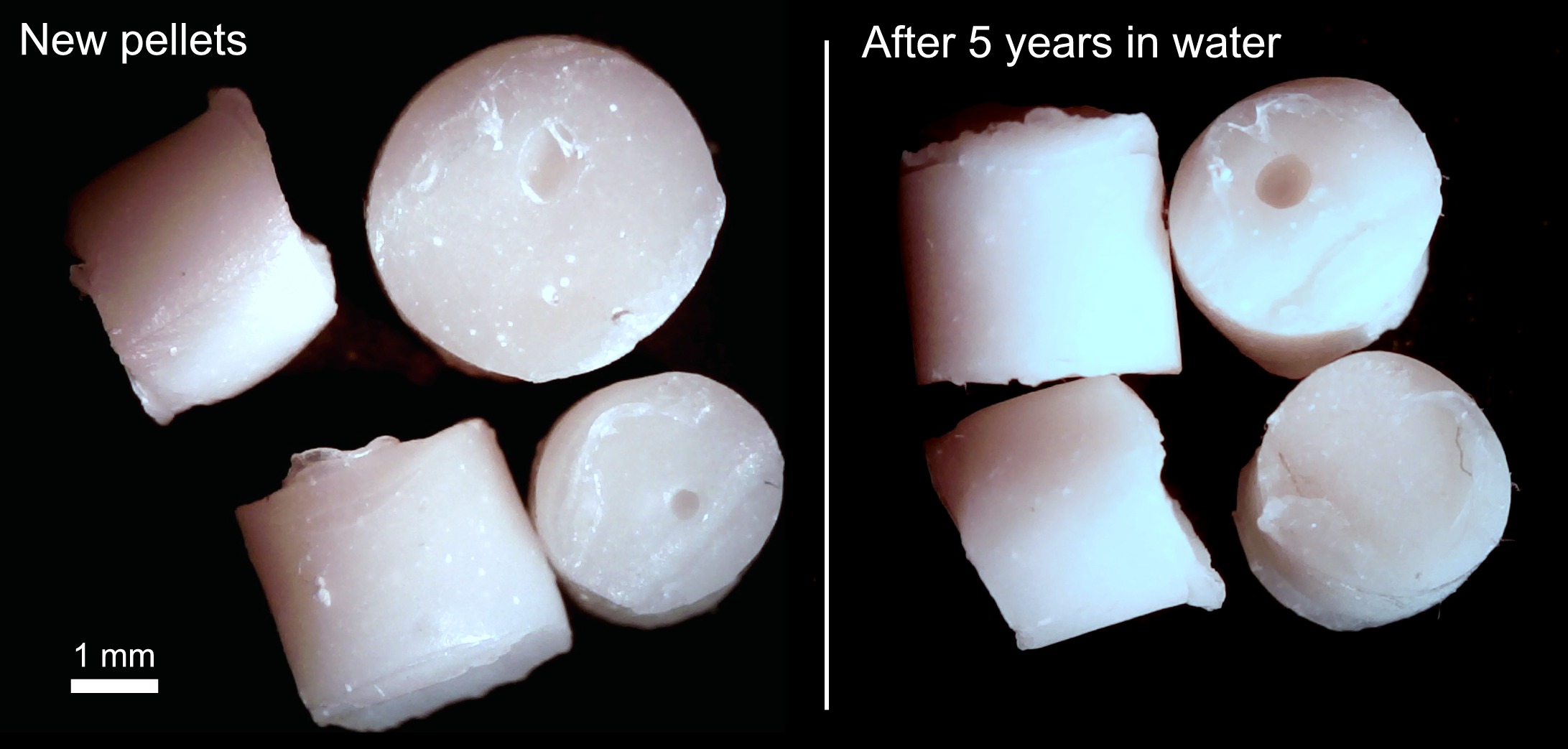

.It was previously mentioned that bioplastics do not simply disappear in the environment, as demonstrated a few years ago by an article showing how a biodegradable bag could remain functional even after years submerged in the sea. This is not surprising but rather a consequence of the fact that compostable plastics are precisely that: compostable. If they were so fragile as to decompose quickly in the environment, especially under low-temperature and low-oxygen conditions like those of the marine environment, they would be impractical. The following photo shows pellets of PHB, polyhydroxybutyrate (PHB), or poly(hydroxybutyric acid). It can be observed that after five years submerged, they have barely undergone any changes, as expected.

What has been said so far makes it clear that bioplastics are not harmless materials that can be abandoned in the environment with the hope that they will disappear on their own. (A special case is agricultural mulch films that can be left in the soil after the harvest period; this topic will be addressed in a later post in this blog.) Similar to conventional plastics, bioplastics are materials designed for specific uses and can help solve certain problems, such as the carbon footprint associated with the use of fossil resources. However, they will not by themselves solve the issue of plastic dispersion in the environment, which is fundamentally a waste management problem, not a material science problem.